3.3 KiB

Purpose

The Texas A&M Sounding Rocketry Team designs, builds, and flies its own hybrid rocket. As part of its design cycle, static cold flows and static engine tests are performed to chacterize the engine's oxidizer tank, fluid system, and combustion process.

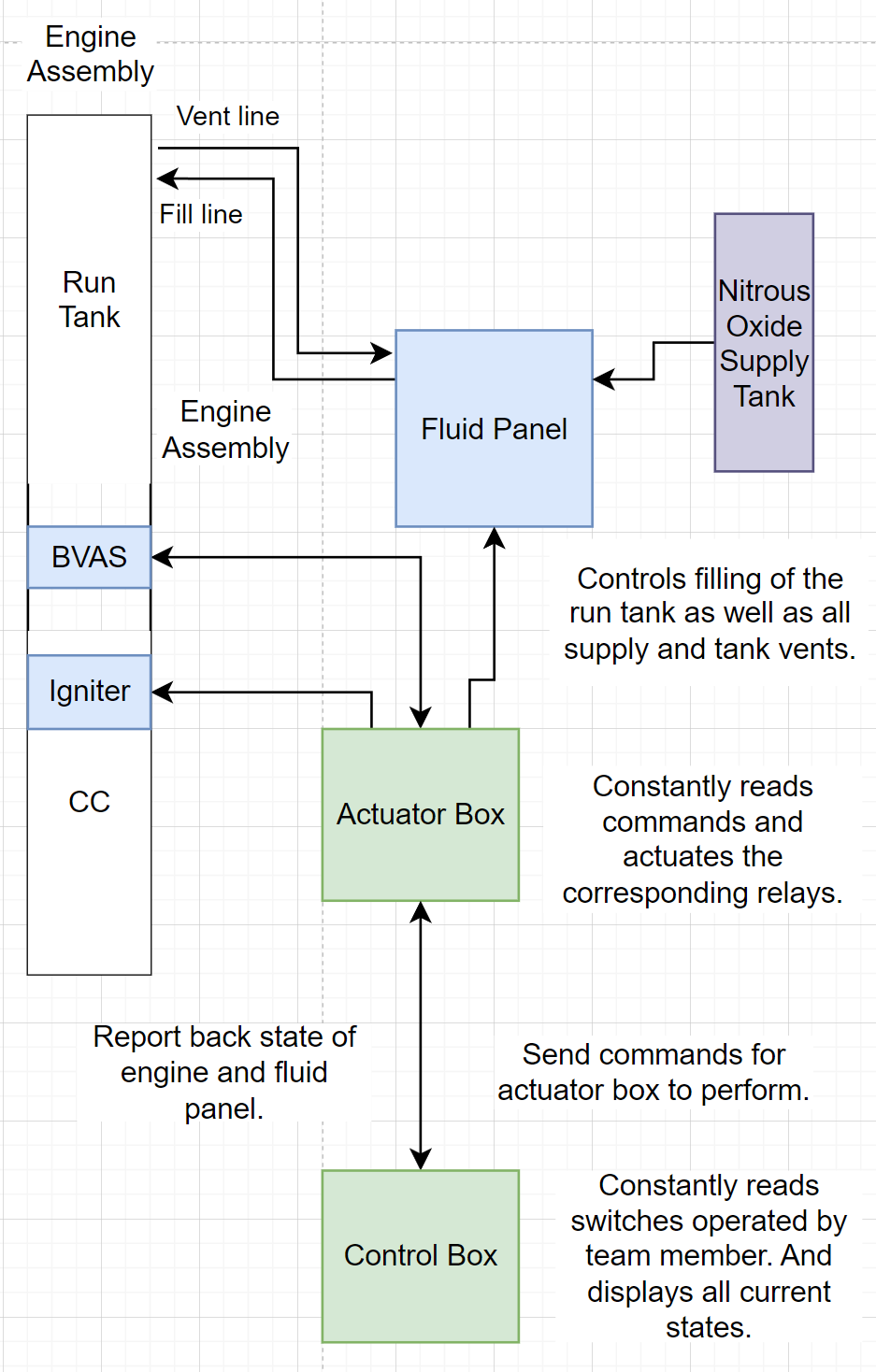

Overall System Design

During a static engine test, we load solid HTPB fuel into the combustion chamber. As part of the test procedure, we load nitrous oxide into the run tank via the fluid panel. We then ignite the starter, and open the ball valve actuation system (BVAS) to begin our combustion cycle.

Concept of Operation

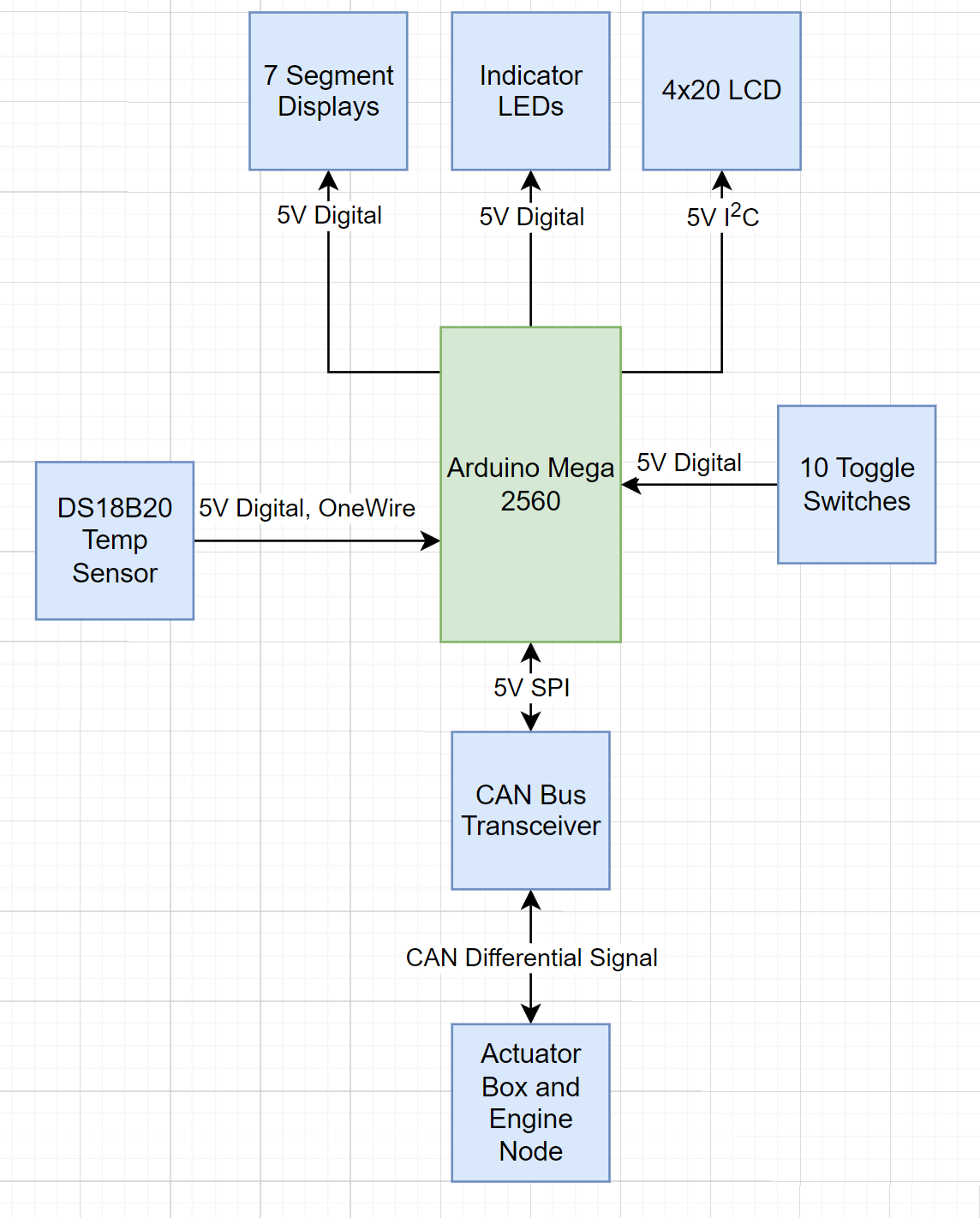

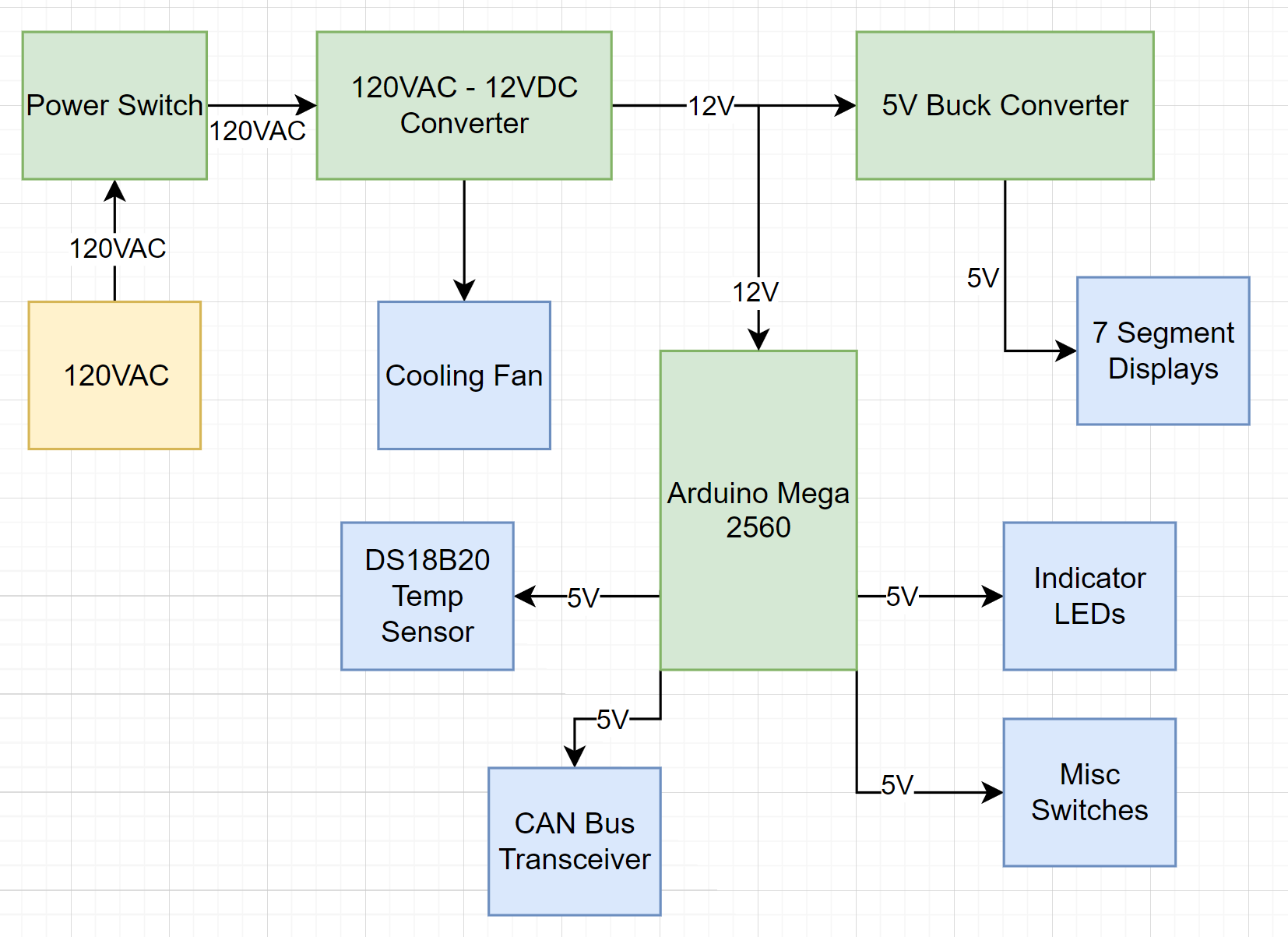

Control Box

The control box is responsible for taking in operator inputs and sending them to the actuator box over CAN. The control box also receives feedback from the actuator box and updates the assortment of LEDs and the LCD screen on the indicator panel.

Logic Diagram

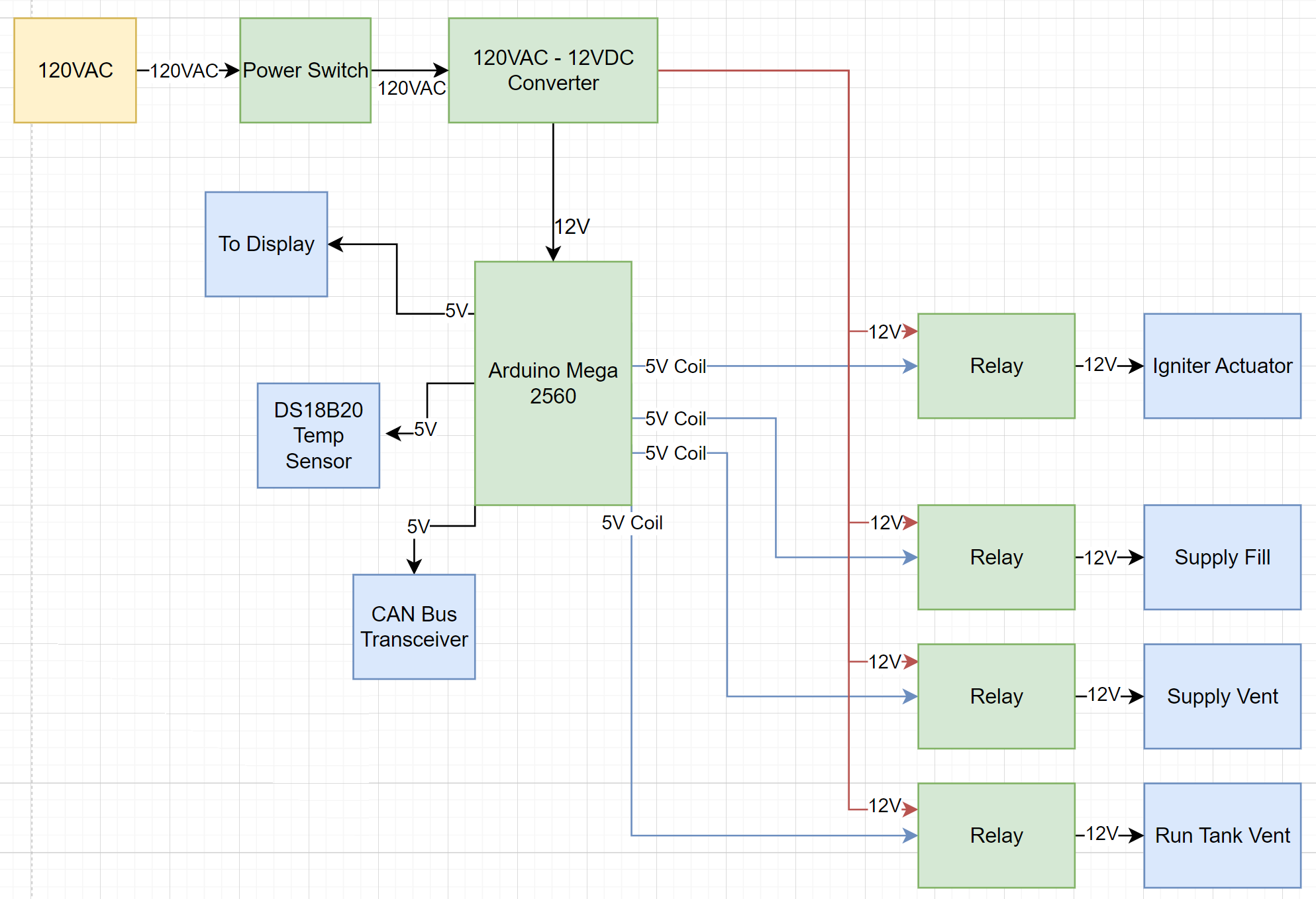

Power Diagram

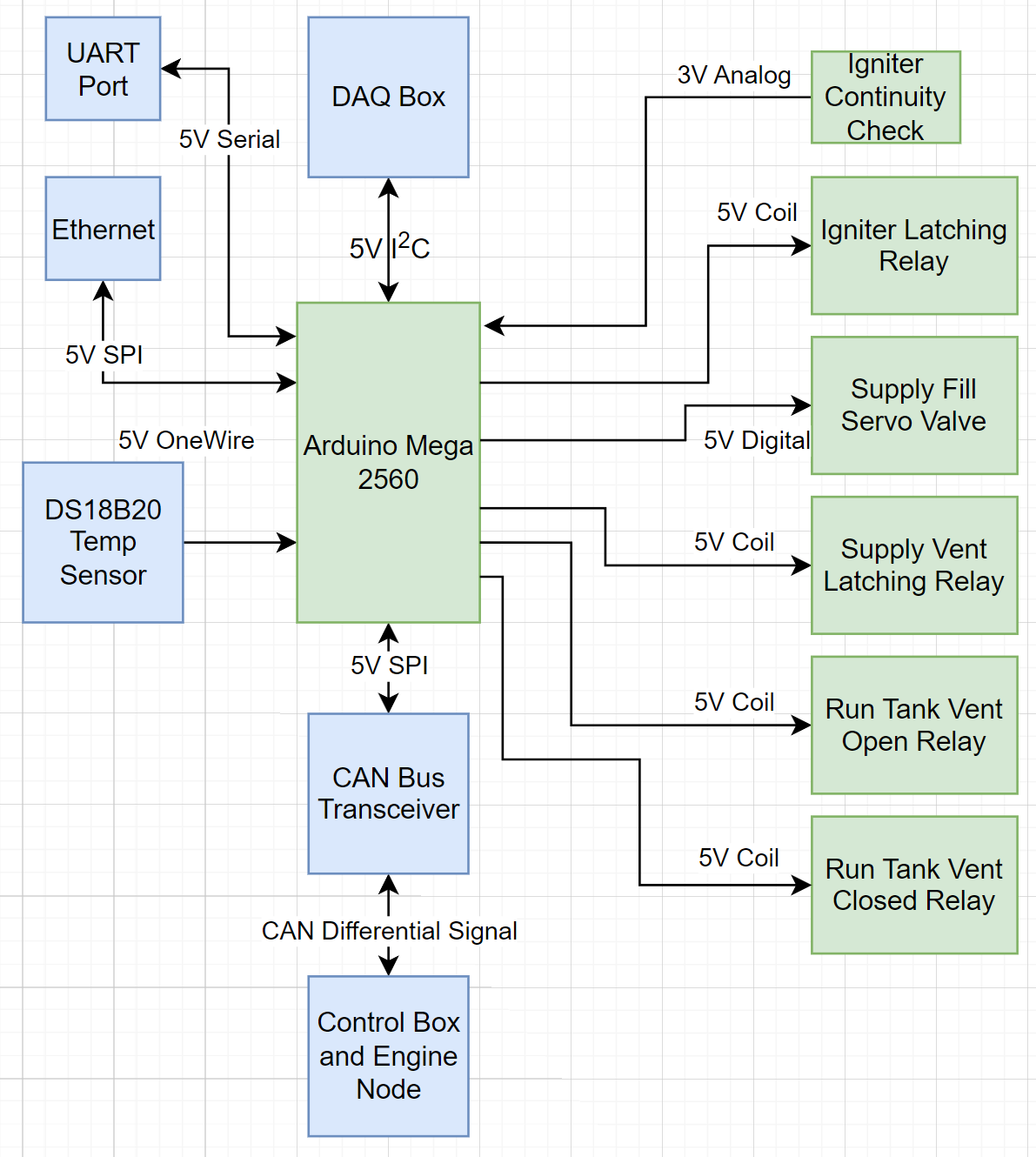

Actuator Box

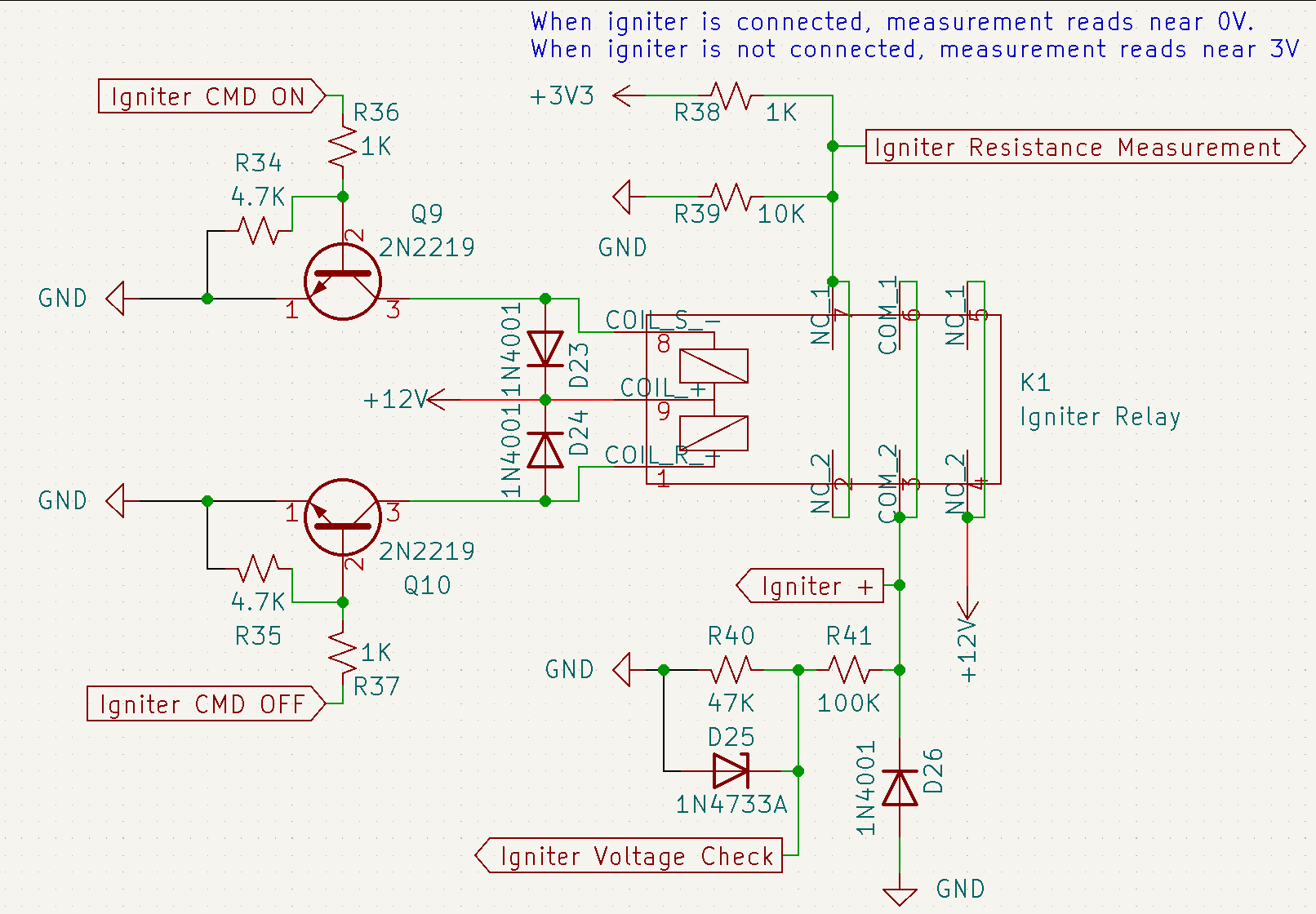

The actuator box is responsible for actuating valves on the oxidizer fluid panel, main throttle valve on the engine, and igniting the starter system. During a test when avionics is deployed, the avionics stack handles engine control while the actuator box controls ground support systems.

Logic Diagram

Power Diagram

Physical Design

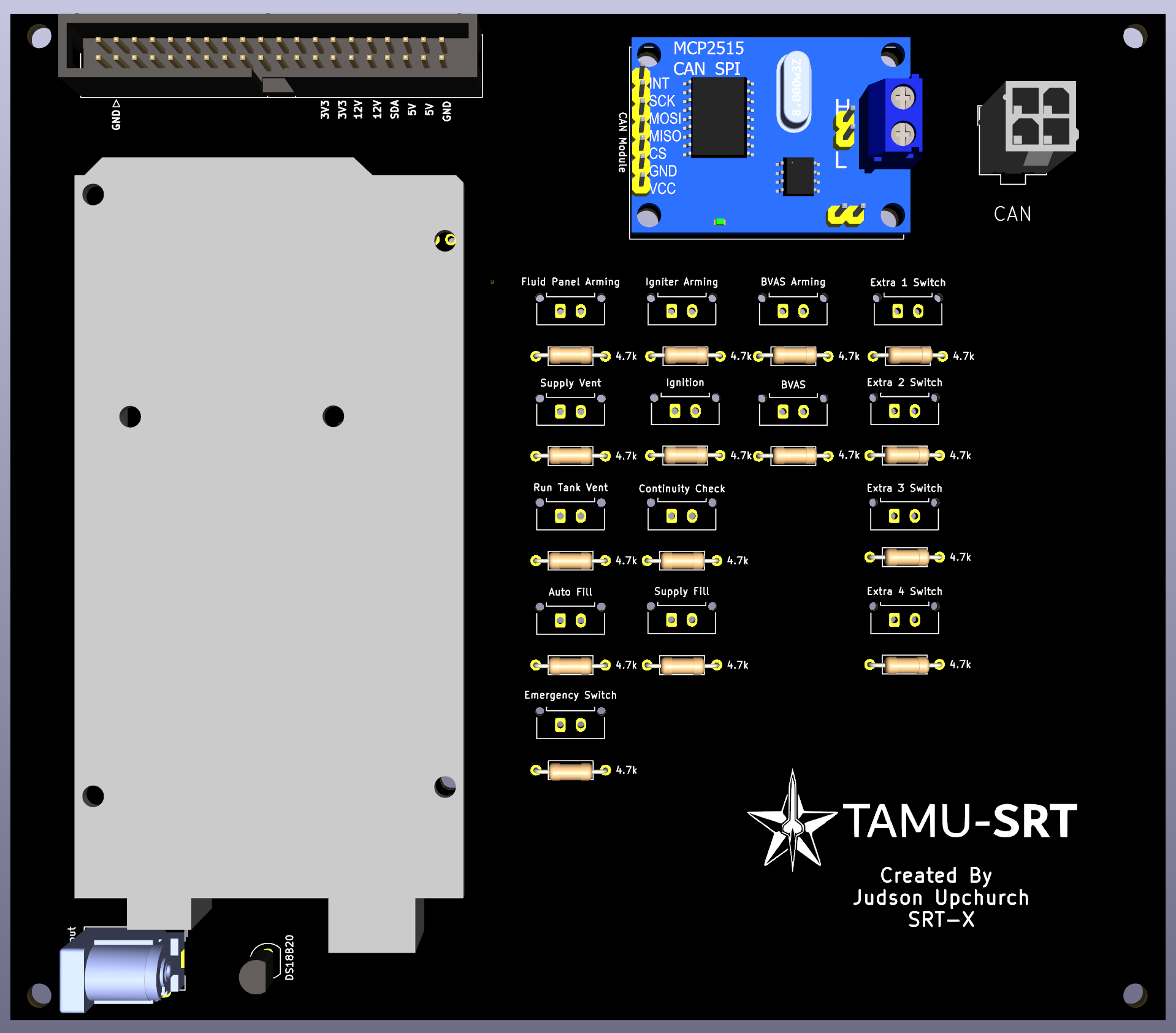

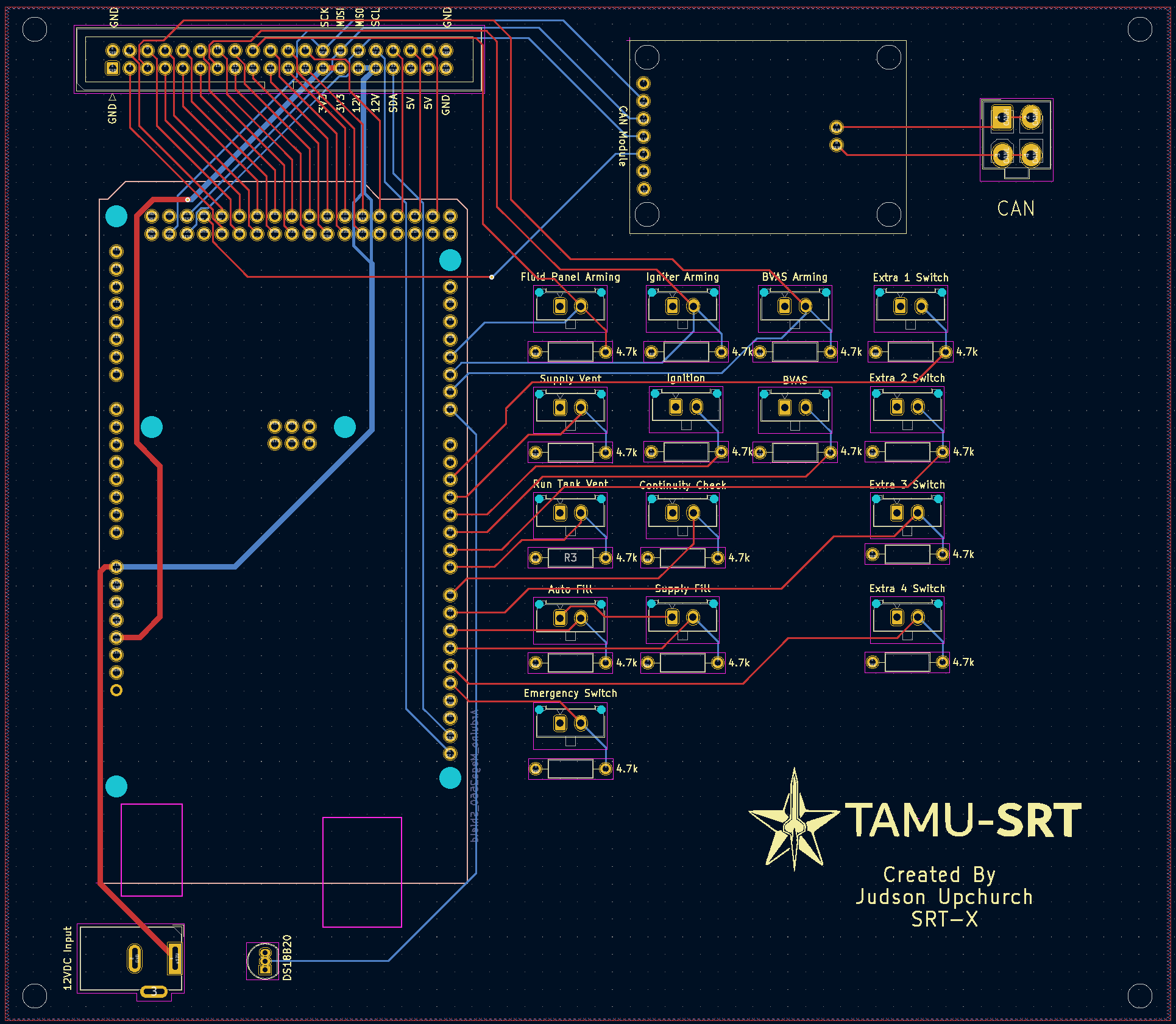

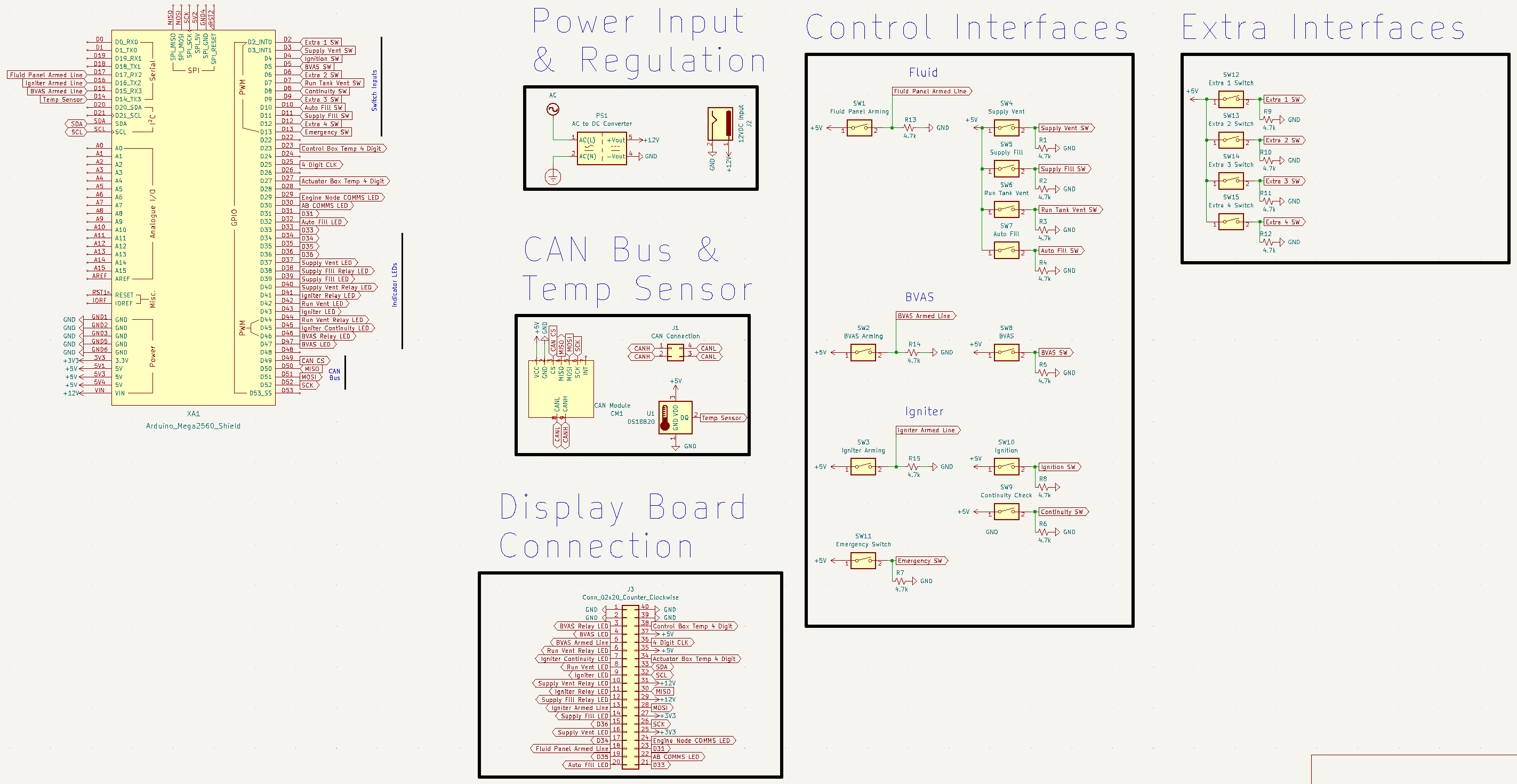

Control Box

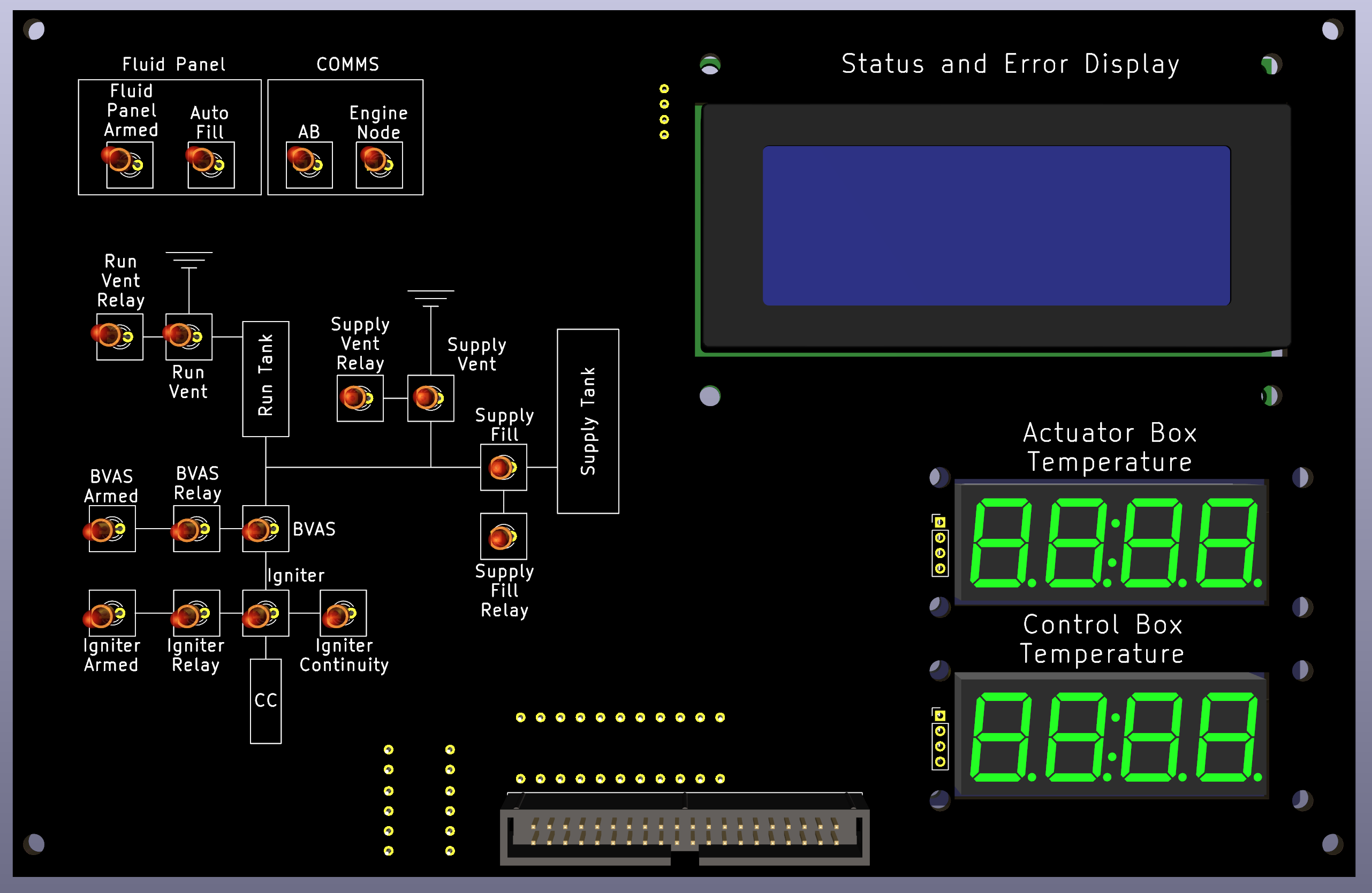

Display PCB

3D Render

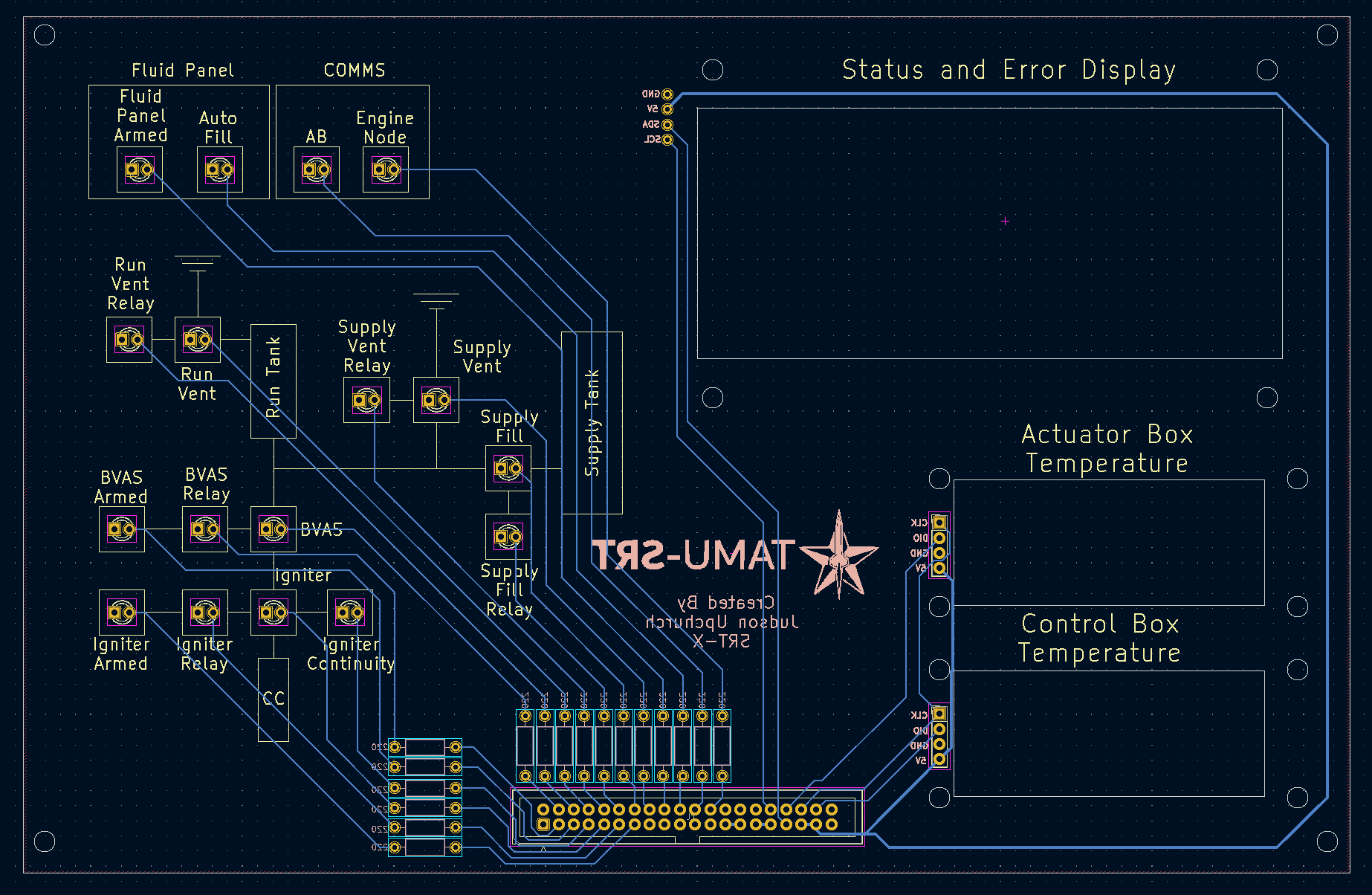

PCB Design

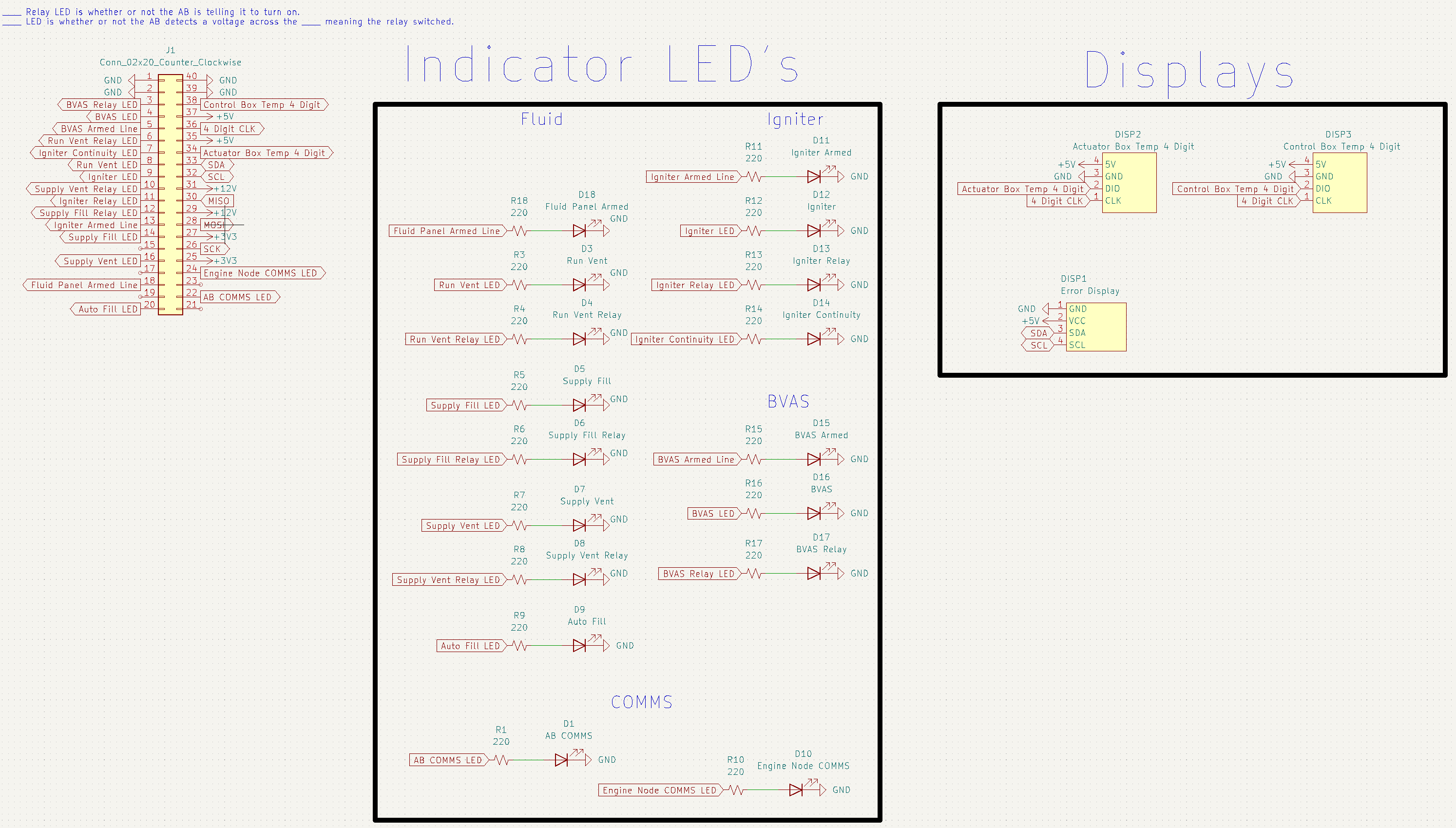

Schematic

Main PCB

3D Render

PCB Design

Schematic

Integrated Assembly

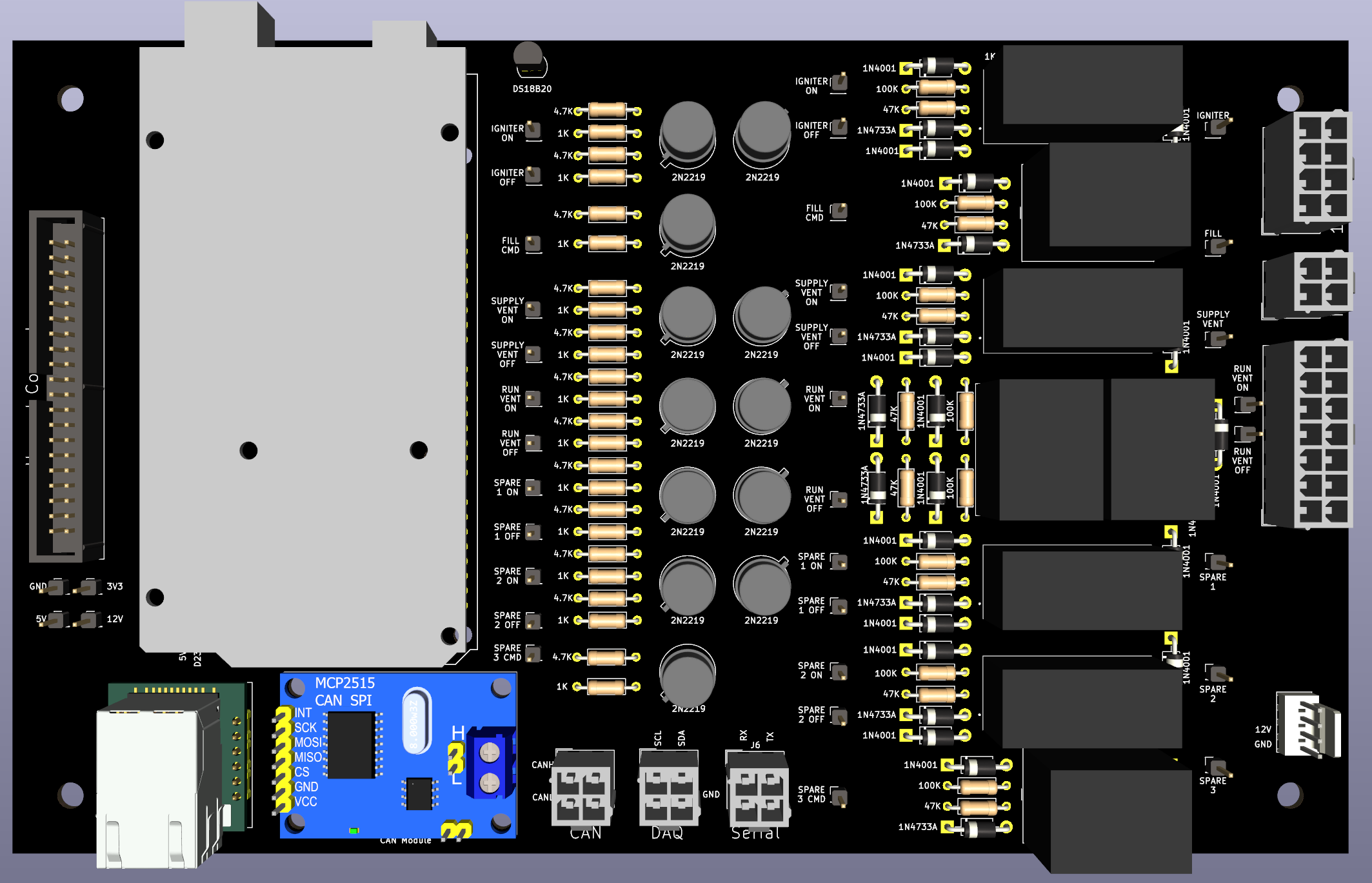

Actuator Box

Actuator PCB

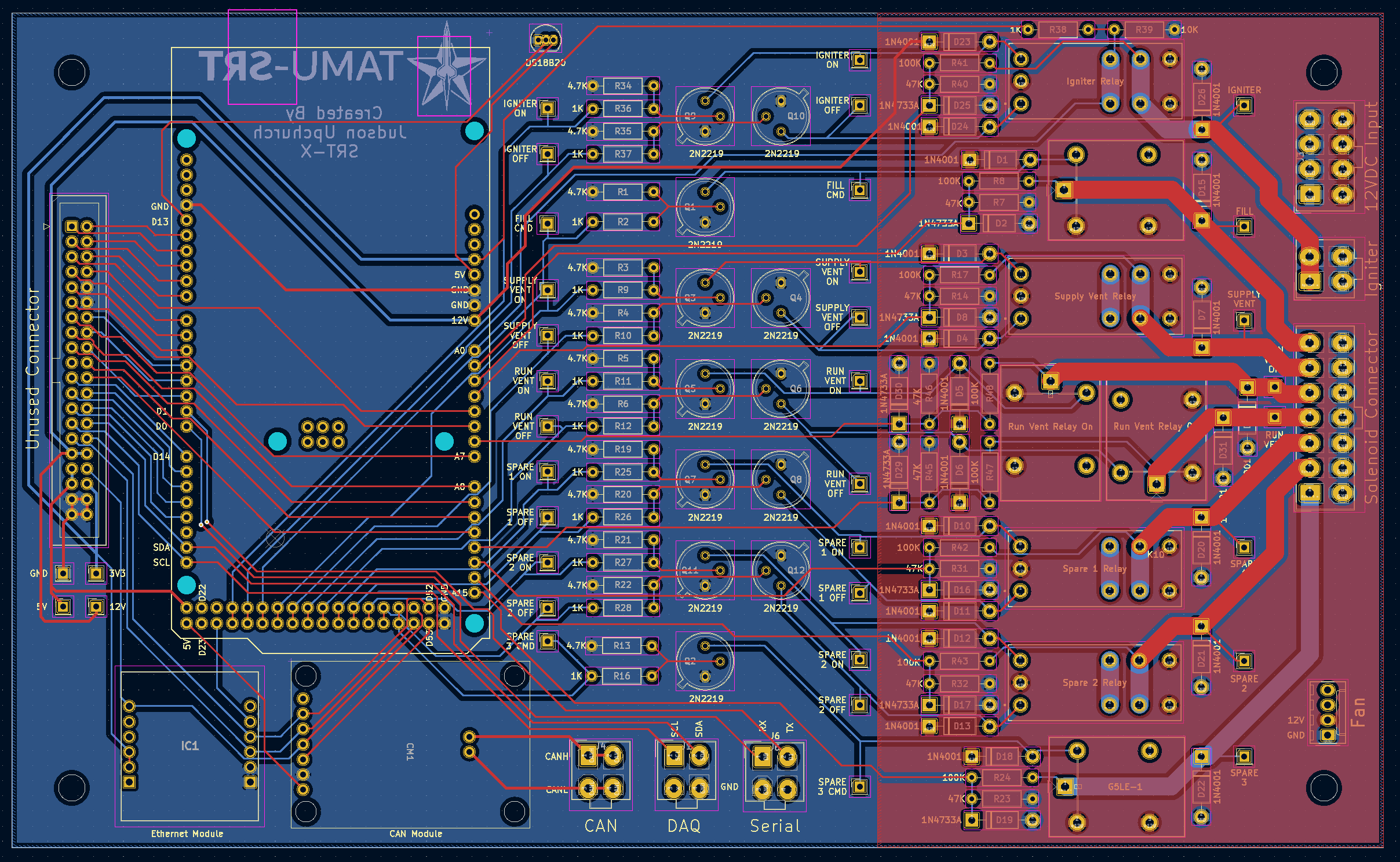

3D Render

PCB Design

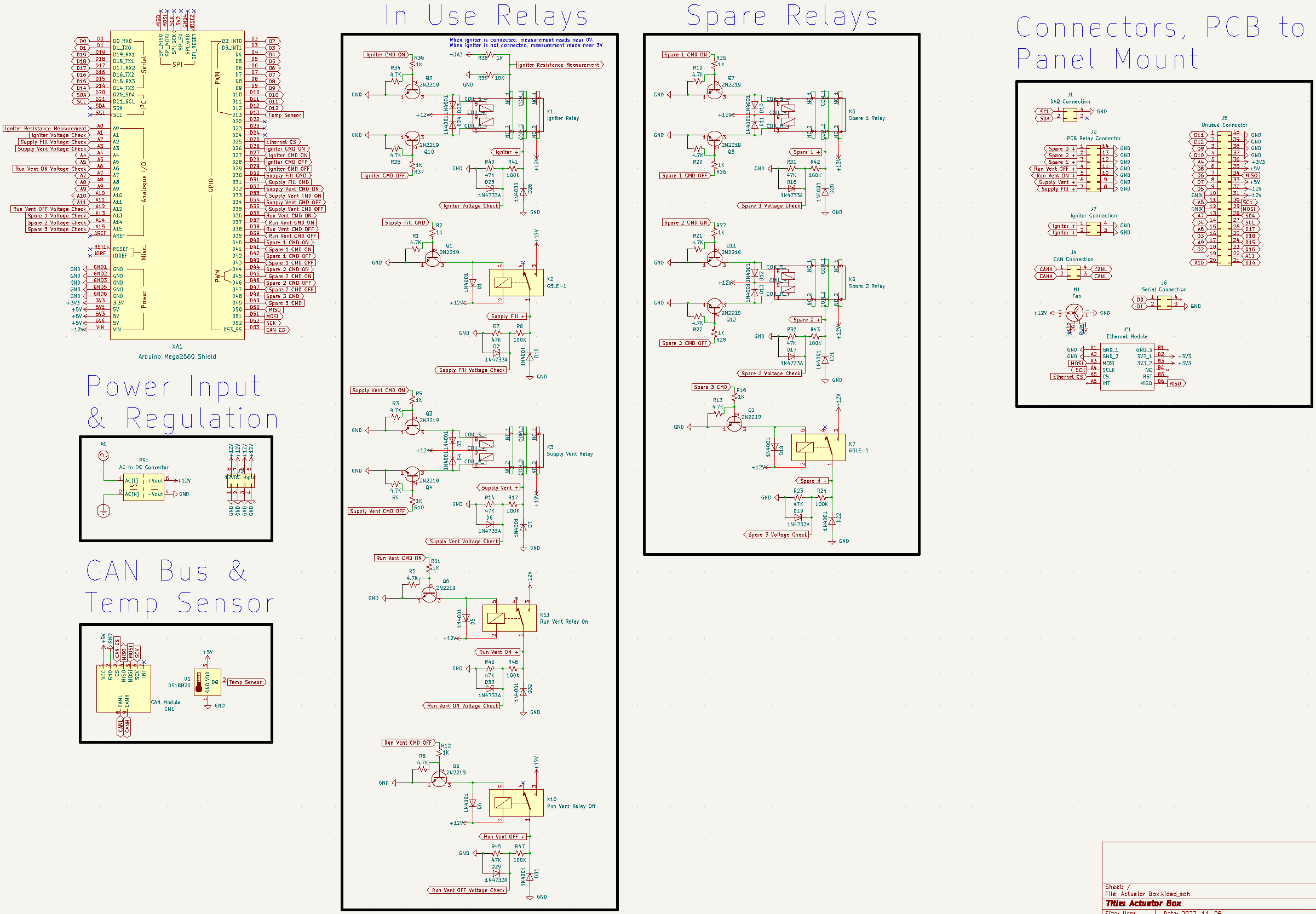

Schematic

Full Schematic

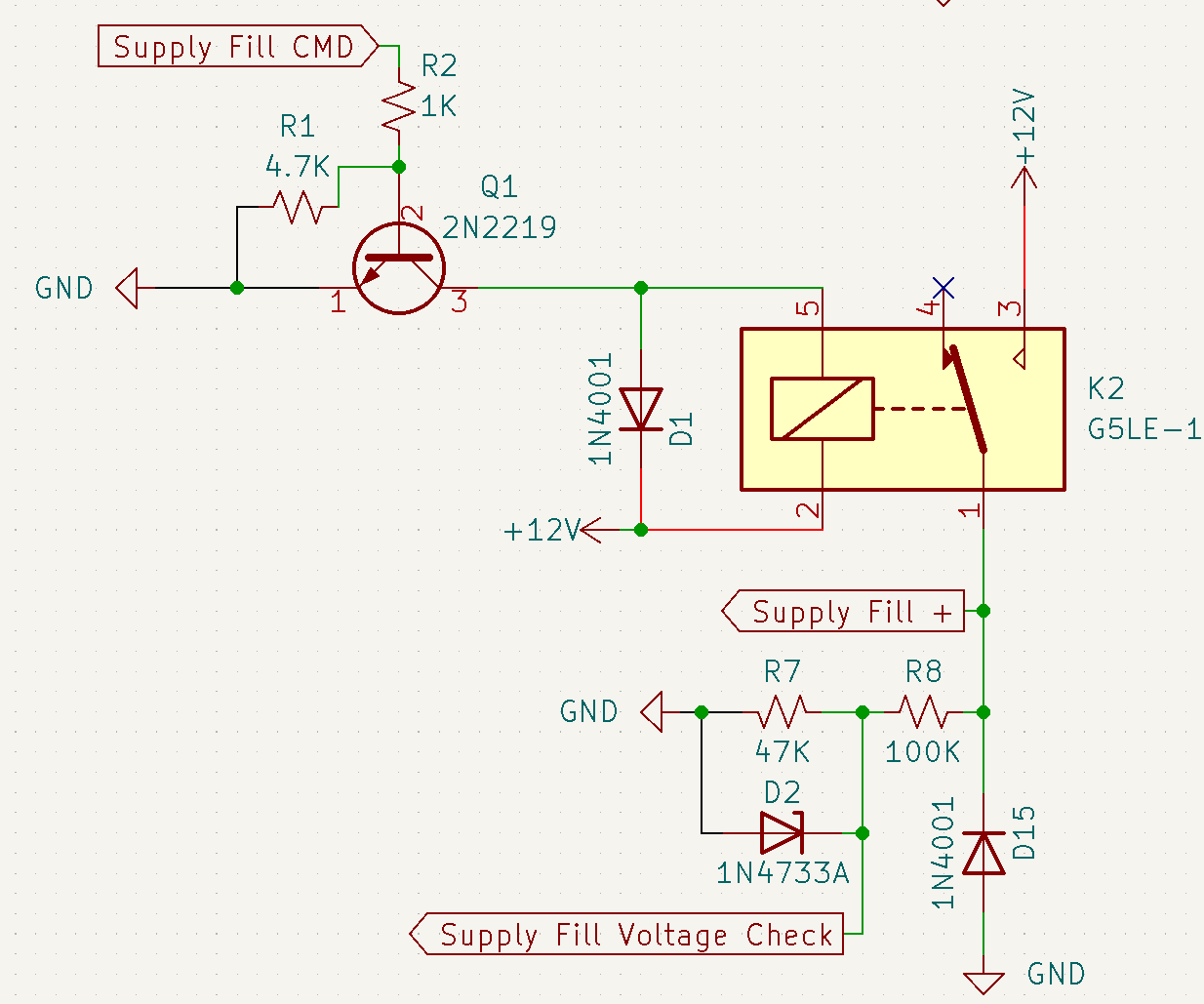

Non-Latching Relay Schematic

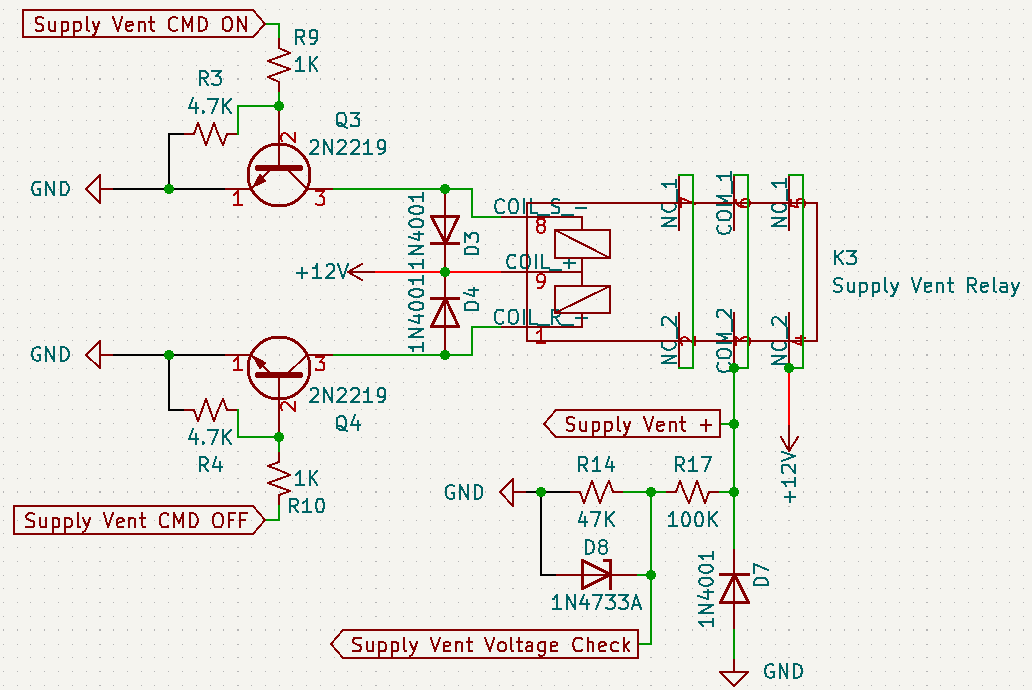

Latching Relay Schematic

Igniter Relay Schematic

Integrated Assembly